Lite-Core Products

Plywood / Plywood + MDF / Door Core / Blockboard / LiteWood FD 30

Lite-Core Products

Here is a brief explanation of our advantages:

- Very High Strength-to-Weight Ratio: At a nominal density of about 370 kg/m3, the Modulus of Elasticity (MOE) of an Albasia plywood panel is approximately 5.3 GPa.

- Sustainable: Albasia falcata is 100% plantation-grown and grows readily without exterior inputs such as fertilizer and irrigation.

- Fast-Growing: Fully-harvestable peeling logs can be achieved after a period of 7 years.

- Friendly: As a nitrogen-fixing tree, Albasia is actually beneficial to the soil and facilitates the growth of other crops. Additionally, the canopy of Albasia provides excellent cover for shade crops such as coffee. It is an ideal species for agro-forestry systems. Carbon sequestration is about 30kg per tree per year.

- Stable: Even at 90% MC, the volume expansion of Albasia is less than 2%.

Plywood

Average Density: 400Kg/m³

Glue: MRE1 or WBP Phenol bonding

Grade: CC/CC; BB/CC; BB/BB

Sizes: 2440/2500mm x 1220mm

Thickness: from 2,7mm up to 44mm

Tolerances: -0/+0,3mm

Testing: CE4

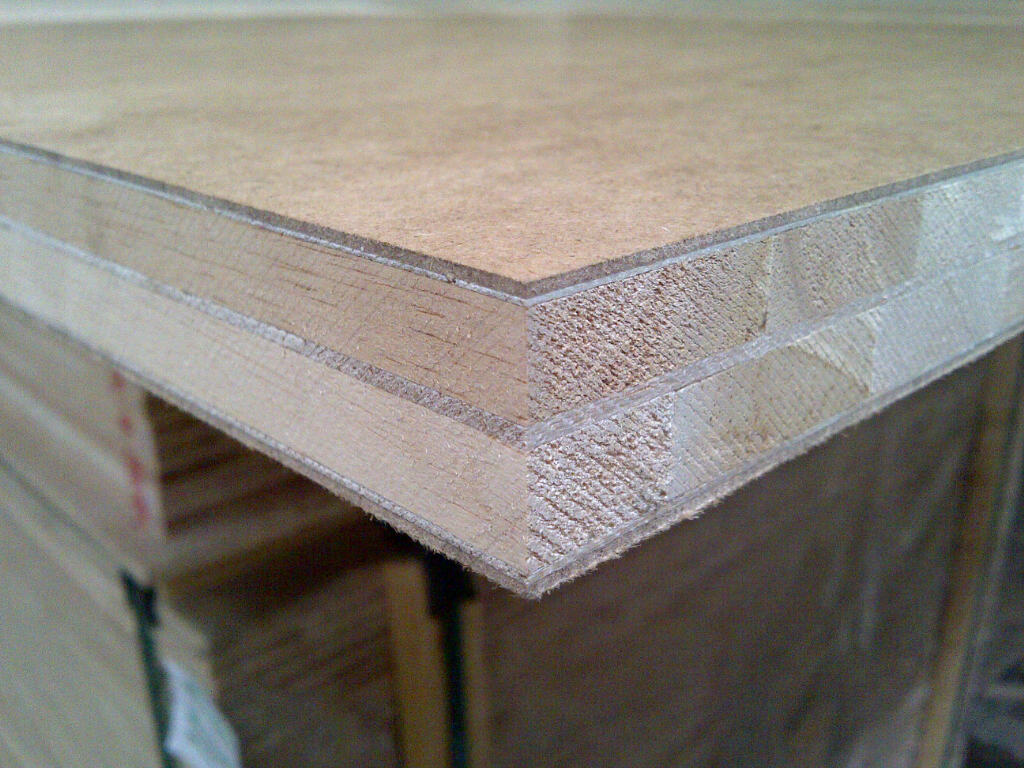

Plywood + MDF

Average Density: 460 kg/m3

Modulus of Elasticity/Bending Strength (MOE)* : 4811 MPa

Screw-Holding Strength: 81 kg

Swelling: 4.5% at 90% MC

Bonding: Poly-Phenolic WBP (CARB P2) or Urea-Formaldehyde (MRE1)

Moisture Content : 10-14%

Construction: MDF - Albasia Plywood - MD

MDF Specifications:

Thickness: 2.5mm

Glue: CARB P2

Density: 750 kg/m3

Panel Size:

Thickness: 8-55mm

Width: 100-1232mm

Length: 100-2451mm

Tolerances:

Thickness: +/-0.3mm

Width/Length: +/- 1mm per running meter

Bow: 3mm per running meter

Block-board (3&5ply)

Average Density: 400Kg/m³

Glue: MRE1 and PvaC E0

Grade: CC/CC; BB/CC; BB/BB

Face/Back : one or two layered veneers // double gross & gross / long

Sizes: 2440/2500mm x 1220mm

Thickness: from 15mm up to 28mm

Tolerances: -0/+0,4mm

Testing: CE4

Door-core (5ply)

Average Density: 400Kg/m³

Glue: MRE1 and PvaC E0

Grade: CC/CC; BB/CC; BB/BB

Face/Back : one layer veneer/p>

Sizes: 720-1220mm x 1800-2500mm

Thickness: from 31mm up to 44mm

Tolerances: -0/+0,4mm

Testing: CE4

LITEWOOD FD 30

Litewood™ FD30 Doorblanks

Chiltern Fire Global Fire

Resistance Assessment

Report No: BMT/CNA/F14192

Valid until 28/8/2019

Examples of Lite-Core usage

Aside from the technical advantages of Albasia such as lightness, stability, and anti-swelling, PRI prides itself on providing a highly technical panel that is precisely calibrated and engineered to the exact specifications of the end-user.

Some of the key differentiators are as follows:

- They only use WBP glue to ensure superior bonding and optimal resistance to moisture.

- They monitor the moisture content at every step of the process.

- They Peel only mature logs, with consistent density profiles and minimal knots.

- They own their plantations.Thus, our we and our clients are not subject to commodity price fluctuations. As a result, raw material costs are low and predictable and the end products are consistent.

- Every panel gets sent through the blow detector to minimize the likelihood of delamination.

- Each panel is manufactured using a 2-step calibration, meaning that both the core and face/back are flat, smooth, and of perfect thickness.

From a social perspective, the Albasia plantations provide consistent revenue for local farmers and support the growth of numerous indigenous shade crops for local Indonesian communities. Multiple community outreach programs have been created throughout the years to promote awareness about the benefits of sustainable harvesting.